Processing Machinery

State-of-the-Art Dairy Processing Machinery for Optimal Efficiency

When it comes to dairy production, efficient and reliable machinery is key to maintaining product quality and consistency. The following processing machines are designed to streamline various stages of production, from packaging to heat treatment, ensuring optimal performance in any dairy plant.

Cup Filler

This machine automates the process of filling cups with liquid or semi-liquid products such as yogurt or cream. Cup fillers are available in different configurations, ranging from semi-automatic to fully automated systems, offering flexibility for different production scales. This equipment provides precision, reducing waste and increasing production efficiency.

Milk Pasteurizer

A milk pasteurizer is essential for ensuring the safety of dairy products by heating milk to a specific temperature to kill harmful bacteria. Modern pasteurizers come equipped with temperature control systems and can handle various batch sizes, making them suitable for both small-scale and industrial production. The pasteurization process is vital to meet health regulations and maintain the nutritional quality of milk products.

Coolers

Coolers are used to rapidly chill milk or dairy products after pasteurization to prevent bacterial growth. They are crucial in maintaining the freshness and shelf life of dairy goods. These units are available in different sizes and capacities to suit specific cooling needs, ensuring that products stay at the optimal temperature during storage and transport.

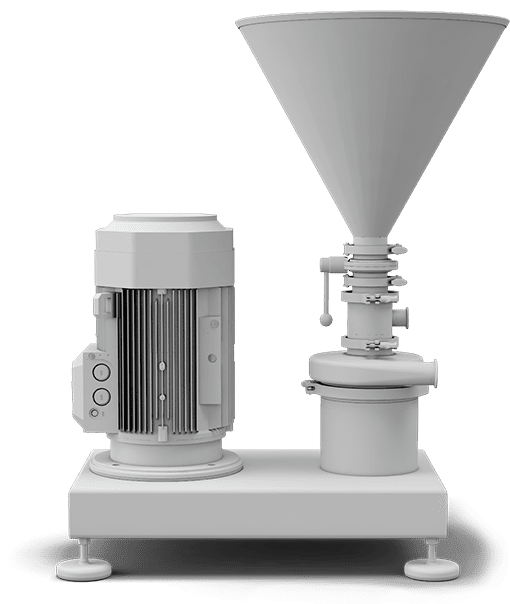

Tri Blender

The tri blender is used to mix powders or other ingredients into liquids, offering fast and efficient blending for products like milkshakes, creams, or yogurt mixtures. The equipment ensures homogeneity and can handle both high and low-viscosity fluids, making it a versatile choice for dairy processing.

Gable Tops

Gable tops are used for packaging liquid dairy products such as milk and juices. These packaging machines create convenient, sturdy, and leak-proof cartons that maintain the product’s freshness. They are customizable for different volumes and designs, providing an eco-friendly and practical packaging solution.

Heat Exchanger

A heat exchanger is vital in the dairy industry for processes such as pasteurization, where heat transfer between fluids is required. This machine ensures efficient energy use by transferring heat between milk and water during the heating and cooling phases, thereby speeding up production and reducing energy consumption.

RFS 40 Cup/Tub Filling Machine

This filling machine is designed for filling cups or tubs with dairy products like yogurt, cream, or ice cream. It can be tailored to handle various container sizes and ensures precise filling, sealing, and labeling. This machine is ideal for high-volume production lines, offering reliability and efficiency.